MATERIALS AND CONSTRUCTION SYSTEMS: RESEARCH, NATURE AND TECHNOLOGY

Aktivhaus’ highly energy efficient buildings are based on natural materials and a multi-layered system adaptable to any architectural solution, together with a combination of high technology and research into increasingly environmentally sustainable solutions.

AKTIVHAUS PANELS

The X-LAM panels used in Aktivhaus buildings are manufactured through a certified production process, thanks to compliance with ETA procedures; they have CE marking and are designed from studies and static calculations, as required by the technical regulations for buildings (Ministerial Decree 14.01.2008).

According to the specific design requirements, X-LAM panels may be used for the construction of walls and floors. Thanks to their excellent mechanical properties, they are ideal for earthquake-resistant buildings. Made almost exclusively with timber from sawmills certified by the PEFC (Programme for the Endorsement of Forest Certification), they are biocompatible and sustainable.

NATURAL MATERIALS

The construction materials and elements are natural and regenerate: for example, the X-LAM load-bearing timber structures are made with an adhesive that is totally free from formaldehyde and solvents, and 100% non-toxic.

All the insulation materials are carefully chosen for the best technical qualities in terms of biocompatibility: examples include cork, wood fibre, cotton and sheep’s wool, all of which are breathable.

Wherever possible, Aktivhaus gives preference to the use of locally produced raw materials, which promote respect for a balanced ecosystem and blend in with the environmental context.

MONOLITH SYSTEMS

Aktivhaus has studied and designed the MONOLITH systems with the aim of constructing buildings that combine excellent technical performance with unsurpassed living comfort. All the systems used are constantly evolving: new technologies and materials of the highest quality enable increasingly high performance to be achieved. Aktivhaus designs and creates buildings that are tailor-made for each situation: the MONOLITH systems can be customised and adapted to any building. For this reason, the examples in the preceding pages should be considered as merely for information purposes and not limiting in any way.

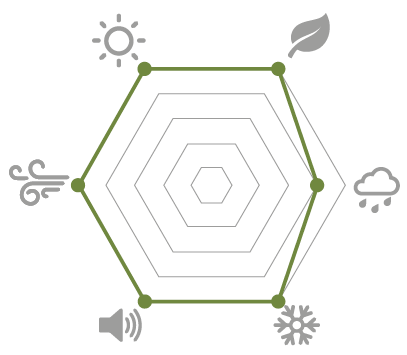

FEATURES

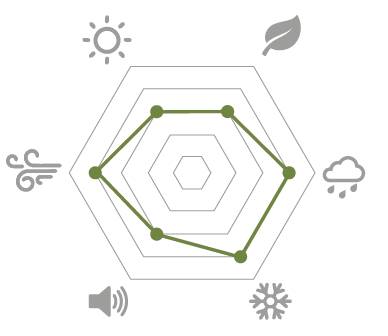

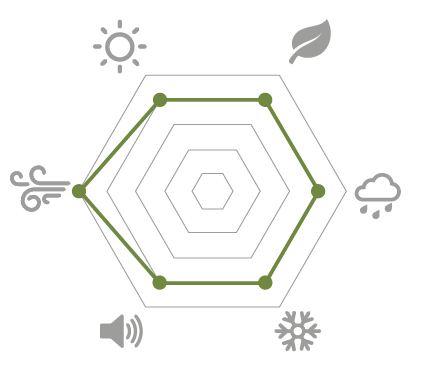

Aktivhaus classifies its building systems using a graphic that shows the system’s performance. The key is provided below:

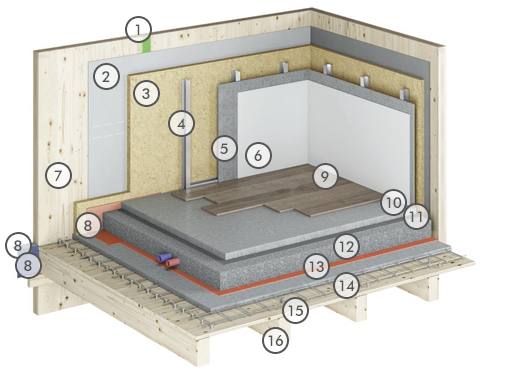

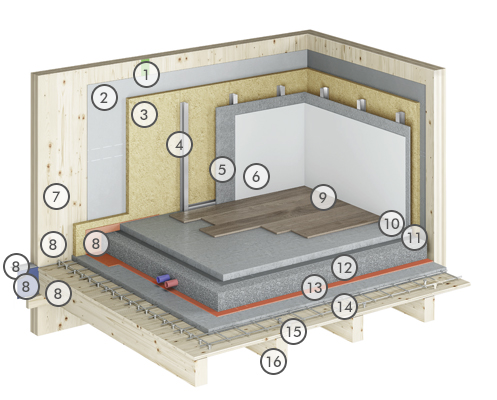

Upper floor with

exposed beams and boards

1. Airtight tape

2. Vapour permeable sheet

3. Fireproof and soundproof rockwool insulation

4. Aluminium structure with cavities for service pipes and cables

5. Gypsum fibre boards

6. High-density plasterboard

7. 96 mm X-LAM panel

8. Anti-vibration strips

9. Parquet or ceramic tiles

10. Flooring screed

11. Under-screed sound insulation mat

12. Lightweight screed for laying service pipes and conduits

13. Sound barrier mat

14. Structural screed with connectors and welded wire mesh

15. 21 mm wooden tongue and groove boards

16. Laminated timber beams

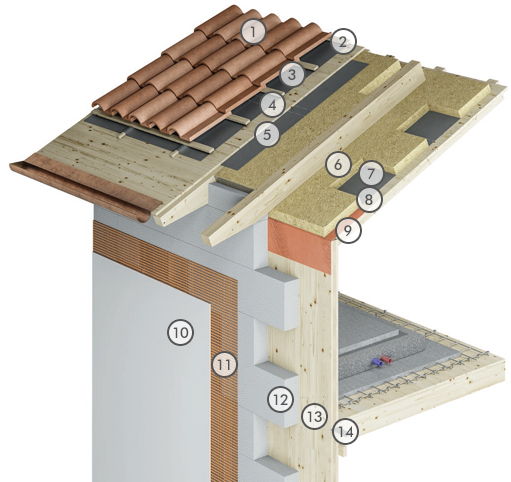

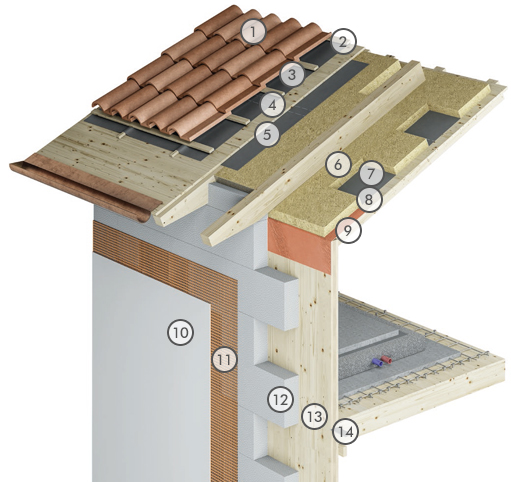

96 mm X-LAM

external wall

1. Tiles

2. Ventilation slats

3. 1st vapour permeable waterproof sheet

4. 21 mm wooden tongue and groove boards

5. 2nd vapour permeable waterproof sheet

6. High density fireproof and soundproof rock wool insulation

7. 3rd vapour permeable waterproof sheet

8. 21 mm wooden tongue and groove boards

9. Laminated timber beams or X-LAM panels

10. Finish plaster

11. Glass fibre mesh

12. Exterior insulation with ETA-approved EPS panels staggered and glued (without plugs)

13. 96 mm X-LAM panel

14. EPDM anti-vibration strip

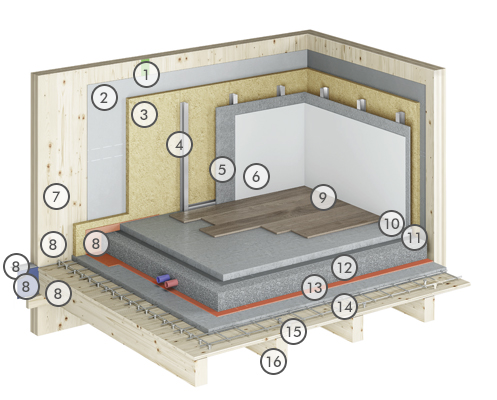

Upper floor with

exposed beams and boards

1. Airtight tape

2. Vapour permeable sheet

3. Fireproof and soundproof rockwool insulation

4. Aluminium structure with cavities for service pipes and cables

5. Gypsum fibre boards

6. High-density plasterboard

7. 150 mm X-LAM panel

8. Anti-vibration strips

9. Parquet or ceramic tiles

10. Flooring screed

11. Under-screed sound insulation mat

12. Lightweight screed for laying service pipes and conduits

13. Sound barrier mat

14. Structural screed with connectors and welded wire mesh

15. 21 mm wooden tongue and groove boards

16. Laminated timber beams

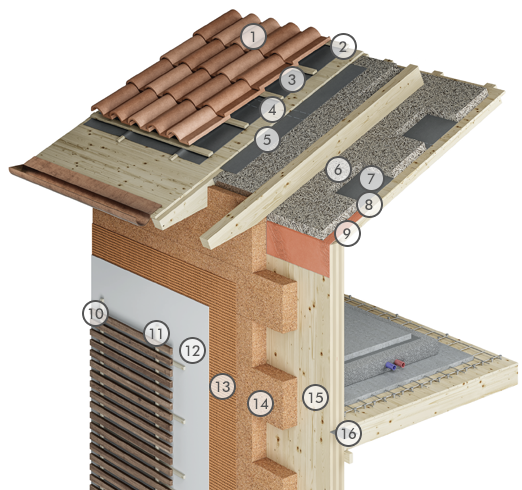

150 mm X-LAM

external wall

1. Tiles

2. Ventilation slats

3. 1st vapour permeable waterproof sheet

4. 21 mm wooden tongue and groove boards

5. 2nd vapour permeable waterproof sheet

6. High density fireproof and soundproof rock wool insulation

7. 3rd vapour permeable waterproof sheet

8. 21 mm wooden tongue and groove boards

9. Laminated timber beams or X-LAM panels

10. Finish plaster

11. Glass fibre mesh

12. Exterior insulation with ETA-approved EPS panels staggered and glued (without plugs)

13. 150 mm X-LAM panel

14. EPDM anti-vibration strip

Upper floor with

exposed beams and floorboards

1. Airtight tape

2. Vapour permeable sheet

3. Fireproof and soundproof rockwool insulation

4. Aluminium structure with cavities for service pipes and cables

5. Gypsum fibre boards

6. High-density plasterboard

7. 200 mm X-LAM panel

8. Anti-vibration strips

9. Parquet or ceramic tiles

10. Flooring screed

11. Under-screed sound insulation mat

12. Lightweight screed for laying service pipes and conduits

13. Sound barrier mat

14. Structural screed with connectors and welded wire mesh

15. 21 mm wooden tongue and groove boards

16. Laminated timber beams

Parete esterna

in X-LAM da 200 mm

1. Tiles

2. Ventilation slats

3. 1st vapour permeable waterproof sheet

4. 21 mm wooden tongue and groove boards

5. 2nd vapour permeable waterproof sheet

6. High density fireproof and soundproof rock wool insulation

7. 3rd vapour permeable waterproof sheet

8. 21 mm wooden tongue and groove boards

9. Laminated timber beams or X-LAM panels

10. Ventilated wall with wooden slats

11. Double load-bearing timber frame

12. Finish plaster

13. Glass fibre mesh

14. Wood fibre insulation panels staggered, glued and plugged

15. 200 mm X-LAM panel

16. EPDM anti-vibration strip

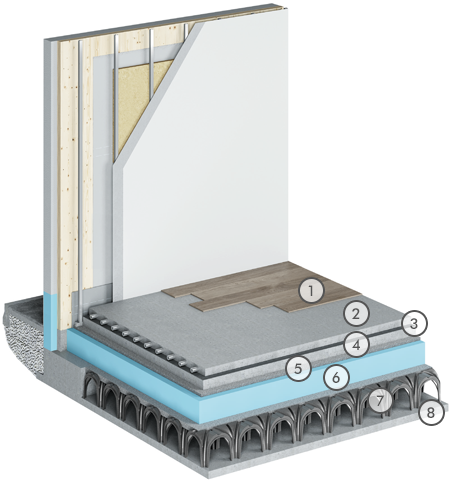

SYSTEMS

GROUND ANCHORAGE

1. Ceramic tiles/parquet

2. Possible screed with radiant panels

3. Acoustic mat

4. Lightweight screed for laying service pipes and conduits

5. Reinforced dividing screed

6. XPS insulation

7. Underfloor cavities with structural slab

8. Lean concrete